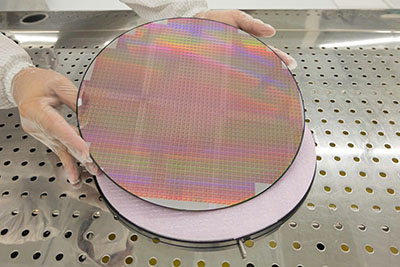

SawStreet specializes in precision wafer thinning for a variety of different substrates. We received full wafers, partial wafers, bumped wafers and single die that require our grinding services. We also stock an assortment of tapes to ensure we offer optimal protection for the variety of different wafer/substrates we receive.

SawStreet specializes in precision wafer thinning for a variety of different substrates. We received full wafers, partial wafers, bumped wafers and single die that require our grinding services. We also stock an assortment of tapes to ensure we offer optimal protection for the variety of different wafer/substrates we receive.

The table below shows the typical thickness for bare silicon wafers prior to being fabricated. As wafers get bigger, they also then need to be thicker. Wafers have to achieve a certain thickness based on diameter so the wafer can bear its own weight without breaking or the wafer does not crack or get damaged during the manufacturing process. Once the wafers complete fabrication, they may need to be thinned for their particular application or in some cases diced before being thinned (Dice Before Grind - DBG).

On occasions SawStreet has received multi-project wafers where the customer may require certain die from the wafer or wafer sections to be thinned to different thicknesses. SawStreet has the flexibility to handle these situations and depending on the wafer can either thin sections of the wafers to different thicknesses or thin individual die after the wafer has been singulation.

| # | Wafer Size | Typical Thickness |

|---|---|---|

| 1 | 300mm / 12 in. | 775 μm |

| 2 | 200mm / 8 in. | 725 μm |

| 3 | 150mm / 6 in. | 675 um |

| 3 | 100mm / 4 in. | 525 um |

Dice Before Grind (DBG) can be beneficial for many customers. In some wafers backside chipping or cracking can be a problem for certain wafers. DBG reverses the process from grinding then dicing to peforming a dicing step that does not fully singulate the wafer. The wafer is then diced to a depth greater than the required final thickness (trenching). The wafer is then thinned to the required thickness which singulates the die. The thinned wafer is then mounted on tape and the backgrind tape is then removed. Disco has an excellent video showing a simplified version of DBG.